- Anhui Guanzhong Packaging Co.,Ltd.

- Main products: ad*star cement bag, block bottom valve bag, AD STAR bag, Block bottom valve bag, ton bag, block bottom valve sack, pp woven bag, STARLINGER cement bag, FIBC Fabric and Sacks, Flat Woven Fabrics, valve bags, open mouth bags, paper woven laminated bags, 2layers 3 layers kraft paper, BOPP Block bottom valve bag

Home > Company News > type of paper: 70-80gsm craft paper Two Ply Kraft Paper Cement Bag

Company News

Color: white or brown

Number of layers: According to requirement

Measures of the bag: Length As customer's demand

Width: 250mm--750mm

Bags of concrete custom Gusset: As customer's demand

Weight/Sq.m: 70-80gsm/Sq.m

Bags of cement design: according to customer's artwork or design

Print: lexicographic printing ,one side or both side,1-8 colors to choose

Perforation: According to requirement

Top of the bag: Stuck with automatic valve

Bottom of the bag: Stuck

Usage Widely used for Powders, granular, fertilizers, sugar, salt, seed, cereal, animal feed, coffee beans, plastic resins, powder milk, contraction ceramic ect.

kraft paper cement bag feature

High porosity paper allows fine powders to fill quickly and can work without perforations which helps to keep the workplace clean. Wet strength paper and poly-lining mean there is a Valve Bag suitable for virtually all applications.

Valve sacks are also available manufactured from polyethylene or woven polypropylene. Different grades and thicknesses of material are available and the valve type and size can be tailored to your requirements.

SPECIFICATION

| Materials | 100%virgin new PP(polypropylene) granules |

| Size | 39x47x11cm, 50*62*12cm or customized |

| Valve size | 80-180cm |

| Woven Fabric | 10 X 10mesh , customized color , coated or laminated |

| UV Content | 0%-3% |

| Ventilation Property | 30nm3/h-170nm3/h,As customer’s filling machines and filling stuff |

| Net Weight | 25kg, 40kg, 50kg |

| Bag Weight | 50g/pc-150g/pc |

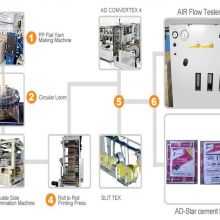

| Equipments | Austria AD*star-kon ,eight sets totally |

| Technology | Hot air welding |

| Top | Vale spout, self-closed mouth |

| Bottom | Square (block ), welding sticker |

| Surface | diamond shape embossing, anti-skidding, easy to stow and transport. |

| Usage /application | Flowing powder , cement , fertilizer , chemicals , flour , monosodium glutamate, putty , try adhesive…all kinds of free-flowing goods. |

| Packing | 500pcs per bale ; 5000pcs per wooden pallet ; 4500pcs per cases ; 6000pcs per double planks(more dangerous when loading ) |

| Production time | Short delivery time, 25-30 days for the first container , then one container per week after prepayment ; according customized |

50kg ppcement bag – Standard Specification

Length: 63 cm

Width: 50 cm

Bottom Height: 11 cm

Mesh: 10Ă—10

Bag Weight: 80 ±2 grams

Color : Beige or White

40kg pp cement bag – Standard Specification

Length:46 cm

Width:37 cm

Bottom Height: 11 cm

Mesh: 10Ă—10

Bag Weight: 50 ± 3 grams

Color : Beige or White

Advantages of our AD Star block bottom bags:

Higher Strength

Compared to other industrial sacks, Block BottomBags are strongestbags in polypropylene woven fabric. That make it resistant to dropping, pressing, puncturing and bending.

Worldwide cement, fertilizers and other industries have observed a zero breakage rate, doing all stages, the filling, the storage, the loading and the transportation.

Maximum protection

Coated with layer of lamination, Block BottomBags keep your goods intact till they are delivered to the customer. Including the perfect shape and intact content.

Reduce Space through Higher Stacking/ Efficient stacking and transportation

Due to perfect rectangular shape, Block BottomBags can be stacked high using space efficiently.And can be used in both manual & automatic loaders.

Fits perfectly with palletizing or truck loading equipment , as it is the same size as other sacks made from different materials.

Easy Transportation

Block BottomBags fits perfectly with palletizing or directly in truck. So its transportation become very easy.

No Spillage

Block BottomBagsare perforated with star micro perforation system which allows air to come out holding the cement or other material without allowing any seepage.

More Market Value through more printing surface

Block Bottom bags takes a box type shape after filling thus offers more printing surfaces on the bag through Top & Bottom Flat which can be read from sides when the bags are stacked.

This increases visibility for the customers and adds to the brand image and better market value.

Sales Manager:Daniel

Mobile Phone:86- 13802155833

E-mail:tjwhoking@163.com

QQ:490045876

SKYPE:antonio87455

WeChat:13802155833

WhatsApp: 86-13802155833