PP woven sackbag from 5kg 100kg loading rice cerealfertilizeranimal feedgrainsagriculture food

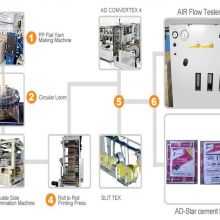

Our products cover Bulk Bags, Multiwall Paper Bags, PE heavy-duty bags, BOPP Laminated Woven Bags, Auto Bags, etc.

The areas of application concentrated on the basic chemical and petrochemical industry, agriculture and garden forestry, construction materials industry.

Sales Manager:Daniel

Mobile Phone:86- 13802155833

E-mail:tjwhoking@163.com

QQ:490045876

SKYPE:antonio87455

WeChat:13802155833

WhatsApp: 86-13802155833

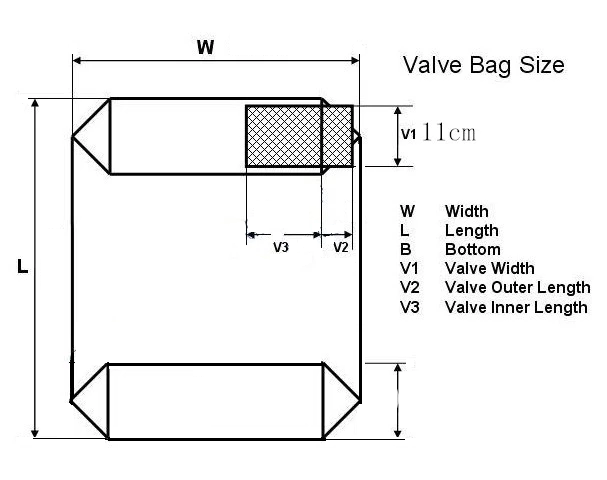

Valve bag is a new and advanced type in packing industry.

It commonly used on automated packing lines where filling efficiency is essential and the speed of filling and closing open mouth bags can be accommodated.

BOPP Film is a durable material that is used for animal feed, seeds, fertilizers, building material, resins, various chemicals, cat litter and so on. In addition, we are also able to customize your bag according to your specific requirements.

We understand that different products have different storage conditions. We can provide but are not limited to UV(Ultraviolet) light resistance, optional handles, color printing, brand design and so on.

Multiwall paper bags are created to provide strong protection for many products. They usually consist of several layers such as 2 layers or 3 layers heavy-duty kraft extensible paper which gives this type of bag high elasticity and high tear resistance. It is a perfect choice for products requiring packaging with high demands for safety and durability.

5 Styles of Multiwall Paper BagsSewn Open Mouth Multiwall Paper Bag is an open mouth bag that is sealed by a sewing thread. It is one of the earliest multiwall paper bag constructions available in the market.

1. Flush Cut Top

2. Gusseted

3. Sewn Factory End with Easy Open Features

Pasted open mouth bag features an open mouth for sewing closed by the user and a flat bottom which helps them to stand upright.

1. Open end flush cut

2. No gusset

3. Square and satchel style bottom

Valve bags are packed by a special filling equipment that deposits material into the bag via a corner opening of the bag. After filling finished, forces produced by the product inside the valve bag allow the bag to self-seal.

1. Satchel style end

2. Comes with a Valve for Filling

3. No gusset

Pinch Bottom Open Mouth bags are ideal for the product which require a barrier liner to optimally preserve the contents inside the bag.

1. Open end stepped

2. Gusseted

3. Factory end folded over and hot melt closed

Sewn open mouth bag is an open mouth bag with a flat bottom and gusseted style. It is available standing up unsupported because of its block base. The unique shape of the bag make it can stack well on the pallet.

1. Open end flush cut

2. Gusseted

3. Pasted"block"bottom

Recently Posted

-

Fertilizer bags woven polypropylene bags and bopp laminated woven bags

August 1, 2023Specifications of Fertilizer bagsMaterial ComositionPolypropylene resinThickness40gsm-90gsmBag Width30cm-120cmBag LengthCustomized Read More

Read More -

type of paper: 70-80gsm craft paper Two Ply Kraft Paper Cement Bag

July 3, 2023Product AttributesModel No.: Two Ply Kraft Paper Cement BagBrand: OEMFeature: Bio-DegradableMaterial: PaperSha Read More

Read More -

Special cement paper bag for masonry decorationkraft paper cement bag feature

July 3, 2023Special cement Paper Bag for masonry decoration descriptionWidth: 250mm--750mmBags of concrete custom Gusset: As custome Read More

Read More -

lexicographic printing 1-8 colors 70-80gsm craft papercement paper packaging bag

July 3, 2023Can't damp to build cement paper packaging bag descriptiontype of paper: 70-80gsm craft paperColor: white or brownNumber of la Read More

Read More